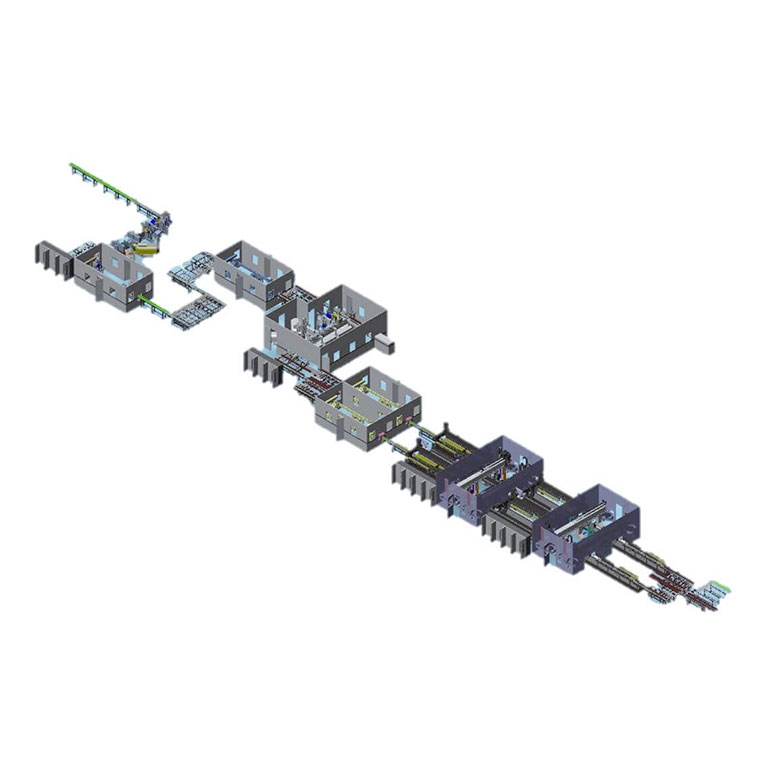

CML Lines

CML branded high-capacity production lines are designed and manufactured according to customer needs.

WATCH THE VIDEO

DOWNLOAD DATA SHEET

CONTACT US

Customised solutions for high production rates in total flexibility. Ask us for what, until now, you could only imagine.

Machine features:

- sturdiness

- extremely simple operation

- simplified maintenance

- protected profiling during processing

- attention to the environment

- major cost-productivity ratio

Obtain more from your Working Process

Systems to support and complete the production process. Integration of different technological brands, managed and included in a Working Process project, with the same quality, efficiency and reliability.

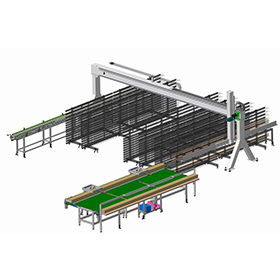

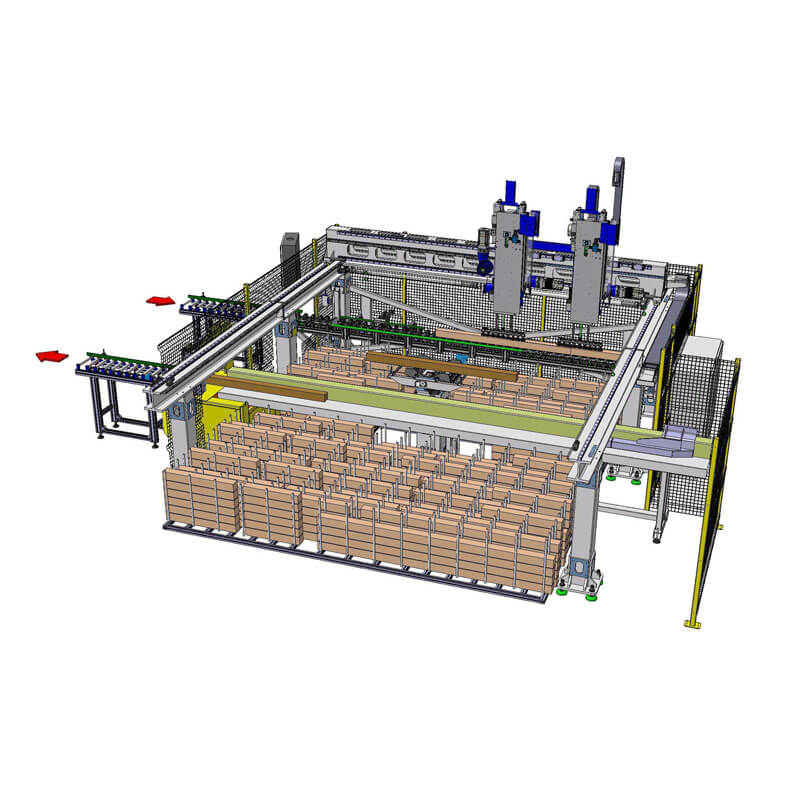

UML multi-level unloading warehouse

Intelligent Finished-Part Storage System. The system caters to the storage of finished parts, up to a maximum of 1500 parts, which can be called up by the operator at the right time and automatically placed in the unloading/quality control area.

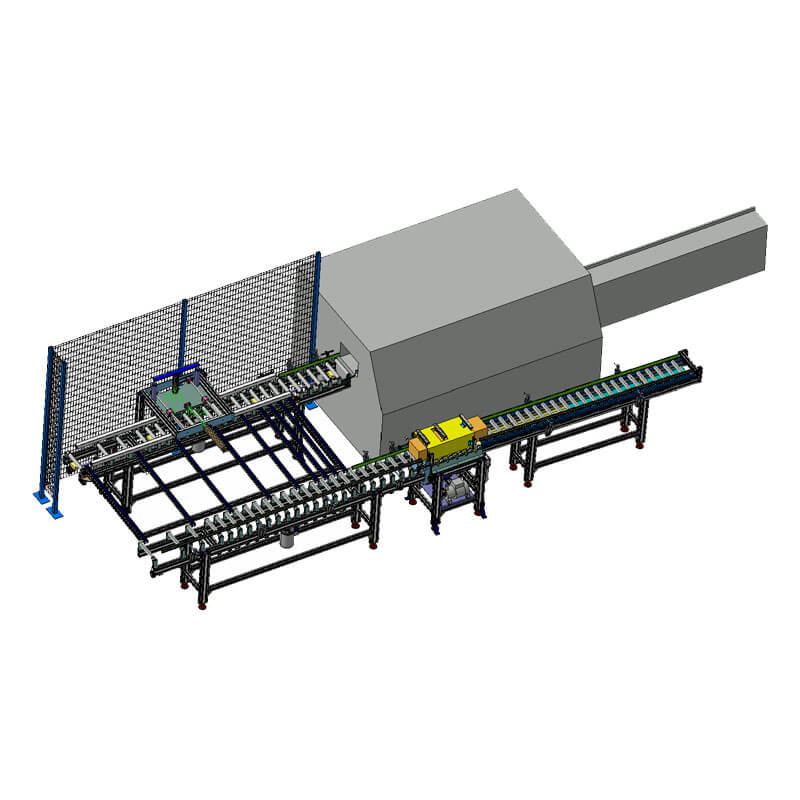

Water shower wetting station

Water shower wetting station and trolley drying system.

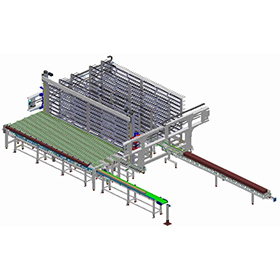

IMML multi-level smart warehouse

Intelligent storage system for single wooden parts.

The system, invented and patented by Working Process in 2010, ensures harmonious management of the material arriving from the first processing phase (cutting and planing): IMML, in fact, picks up and stores the cut-off and planed parts inside it and, at the same time, finishes off the parts on the machining centre according to a logic that optimises the productivity of the centre itself.

IMML part of the M.P.E. process.

LUML multi-level loading and unloading warehouse

Intelligent storage system for single wooden parts. The system ensures the harmonious management of the material arriving from the first processing phase (cutting and planing) and storage of the finished parts up to a maximum of 1500, which can be called up by the operator at the right time and automatically placed in the unloading/control area.